|Decharbonization

From Interior Acoustics Enhancement to Exterior Soil Remediation

|Team

Giovanna Cusciano Oliveira, Astha Agrawal, Divya Gogia, Alessandra Diana De Rada Ocampo

|Faculty

Areti Markopoulou, Nikol Kirova, Daniil Koshelyuk

|Project year

2023-24

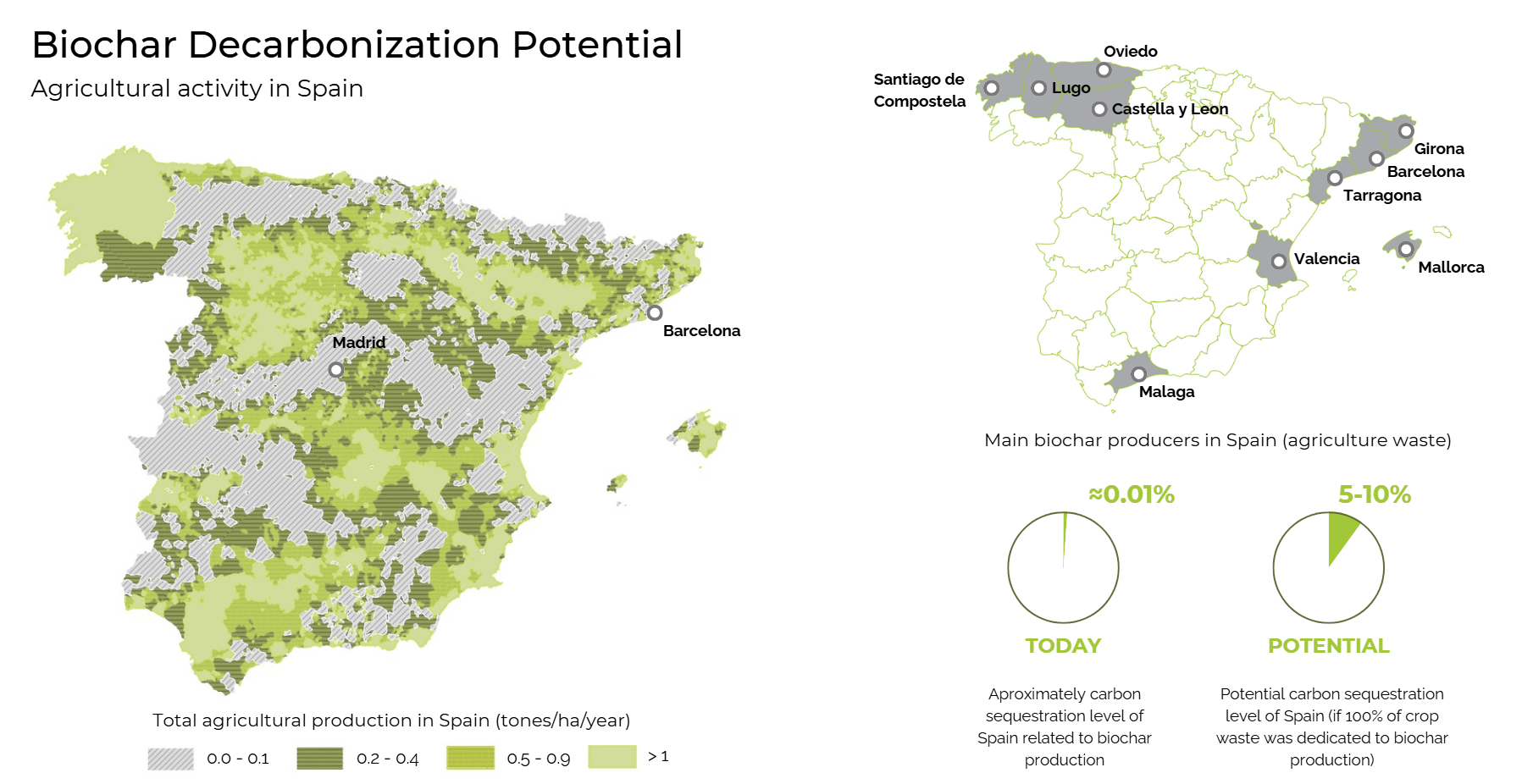

Decharbonization project aims to develop a non-cementitious biochar composite through geopolymerization, transforming it into a viable material for architectural use while amplifying its carbon-sequestration potential.

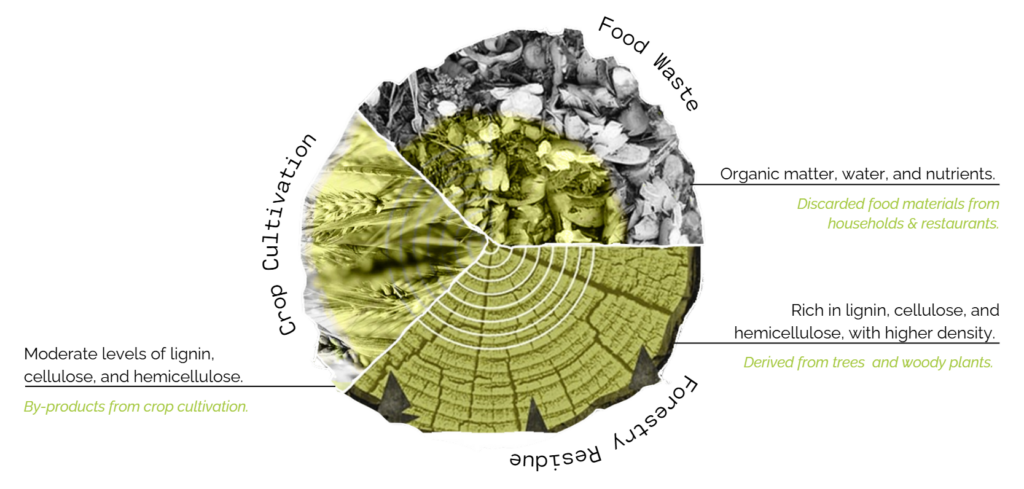

Biochar is a carbon-rich material produced by the pyrolysis of organic waste in a low-oxygen environment. Known for its environmental benefits, biochar has the ability to sequester carbon, improve soil health, and enhance water retention.

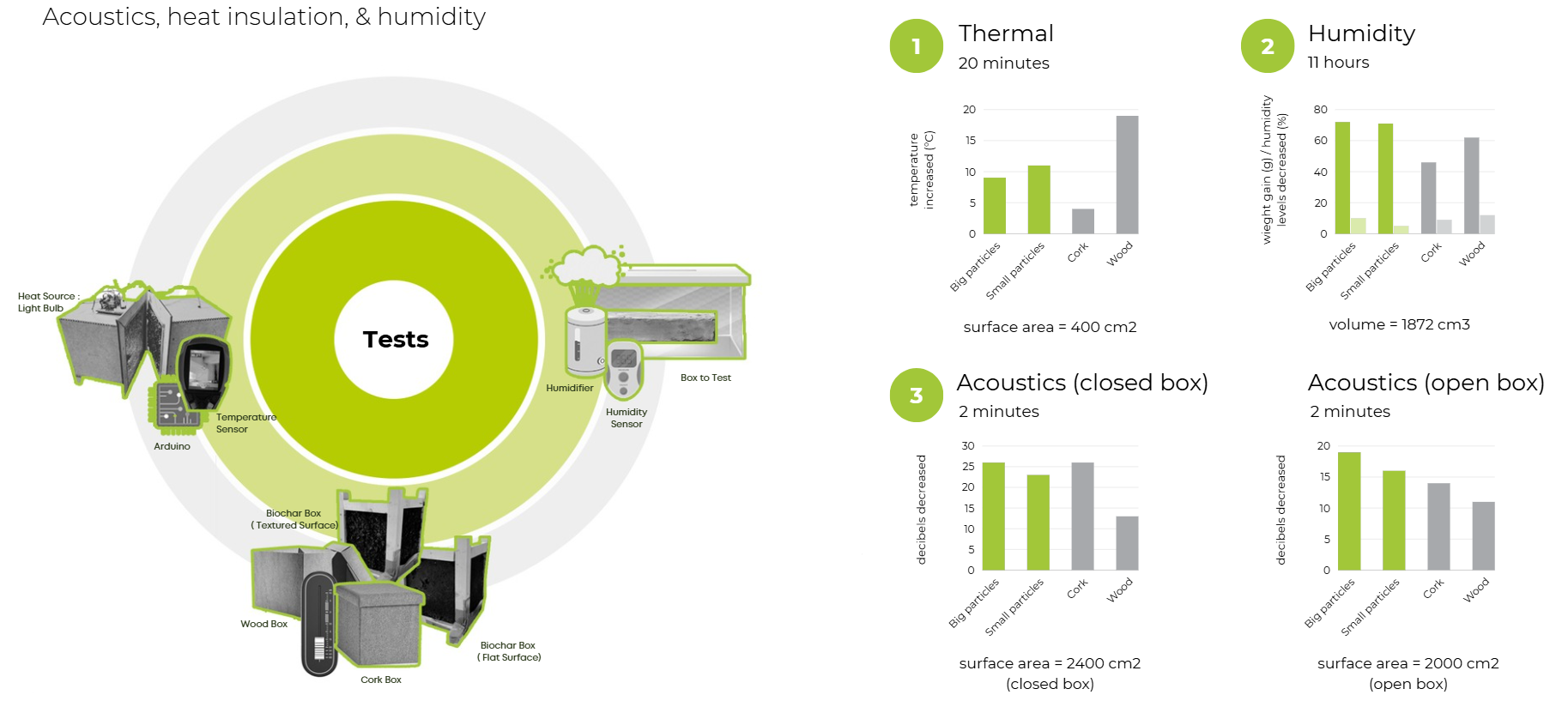

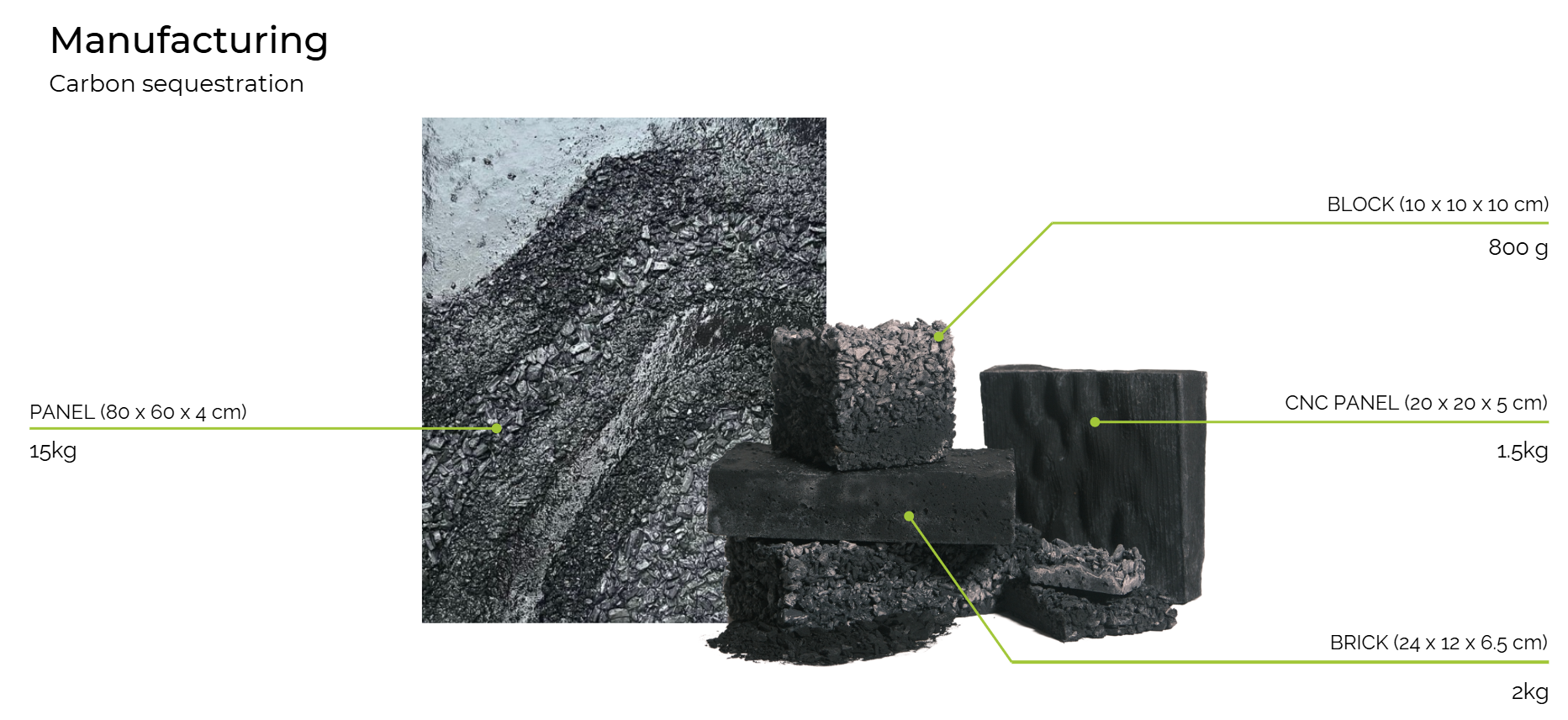

Using an iterative prototyping approach, the research explores biochar’s various properties, such as heat insulation, humidity regulation, and acoustic enhancement while investigating how biochar can be integrated into architectural elements like bricks, panels, and facades. A key focus of the research is maximizing the biochar content in the composite recipe without compromising durability and lightweight performance.

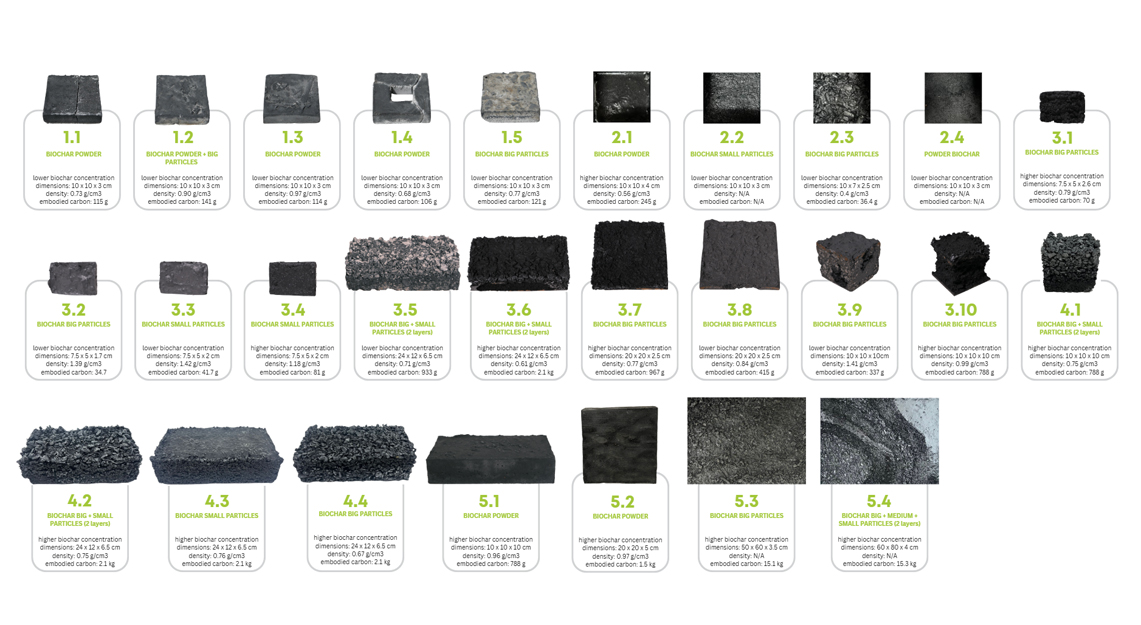

Various particle sizes—large, medium, and small—were tested to assess their impact on density, performance, and energy requirements. Larger biochar granules yielded prototypes with lower density and greater surface area, improving humidity retention, thermal insulation, and acoustic properties. Moreover, this approach reduces preprocessing energy demands, aligning with the principle of “form follows availability,” wherein material characteristics guide design decisions to optimize sustainability.

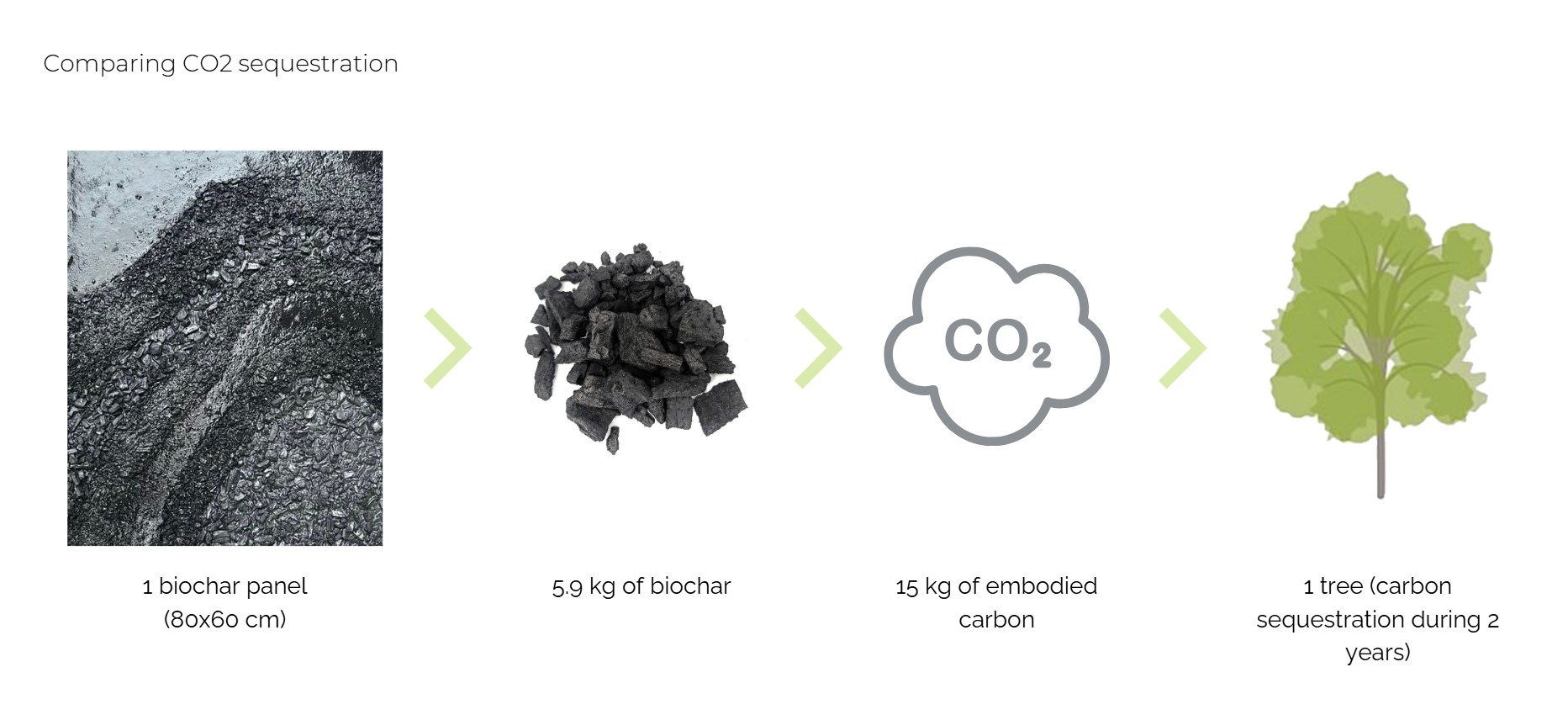

The research reveals that each panel incorporates approximately 5.9 kg of biochar, equating to 15 kg of embodied carbon—the amount of carbon a tree would sequester in nearly two years. By leveraging this inherent carbon-capture capacity, the material has a significant potential to reduce the carbon footprint of construction projects and decarbonize the industry.

Carbon Sequestration Rates of Different Panels

Carbon Sequestration Comparison

Different Granule Sizes

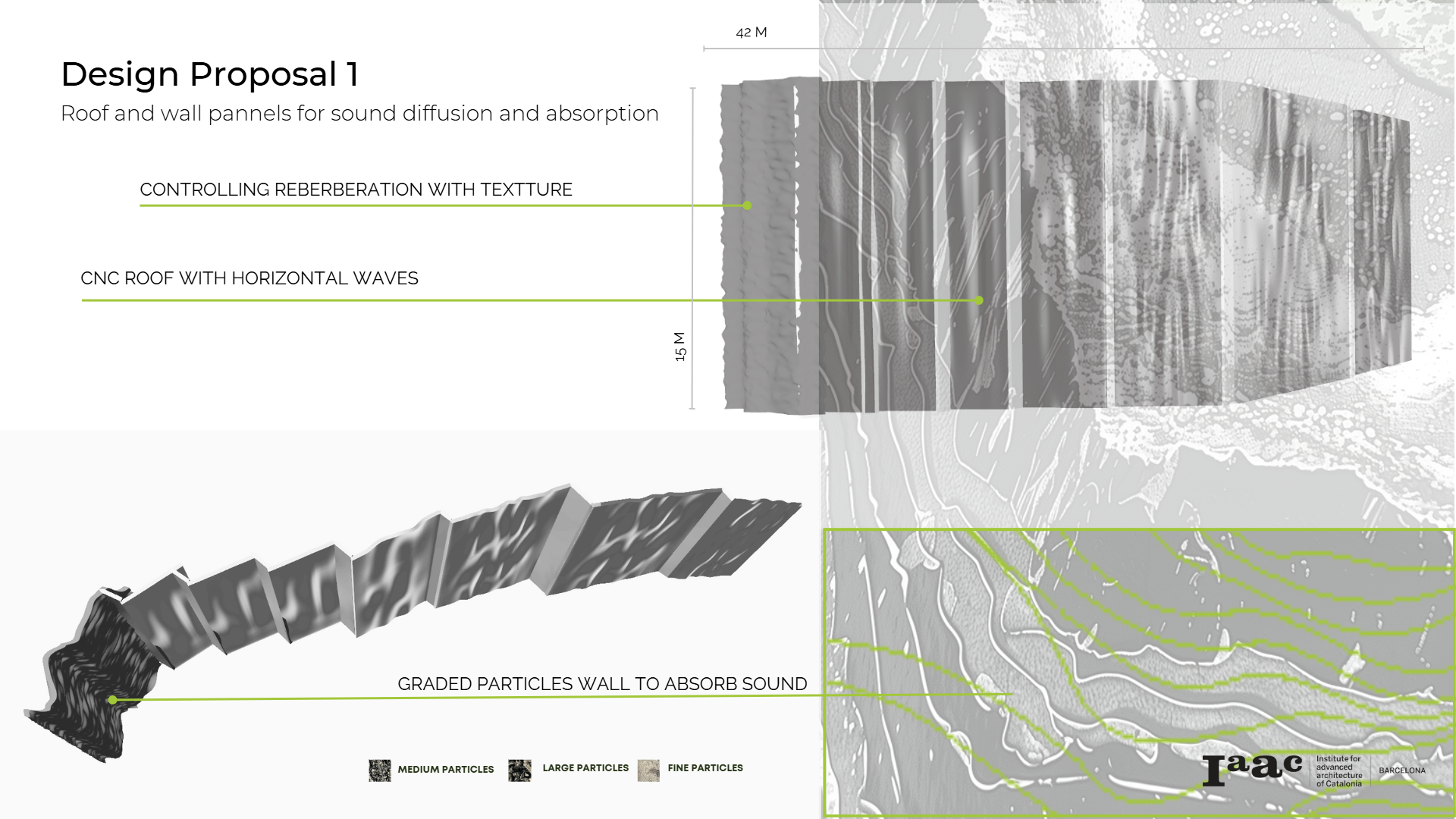

Upon physical prototyping, composite with larger biochar particles demonstrated promising results in terms of acoustic insulation, leading to their integration into two case studies for further performance analysis. The panels were functionally graded, with larger granules strategically placed to maximize sound insulation where needed, while smaller granules enhanced structural stability by increasing density. This graded approach also allowed for optimized acoustic diffusion and absorption, highlighting its potential for tailored performance in specific architectural contexts.

Proposal 1 - Roof and Wall Panels

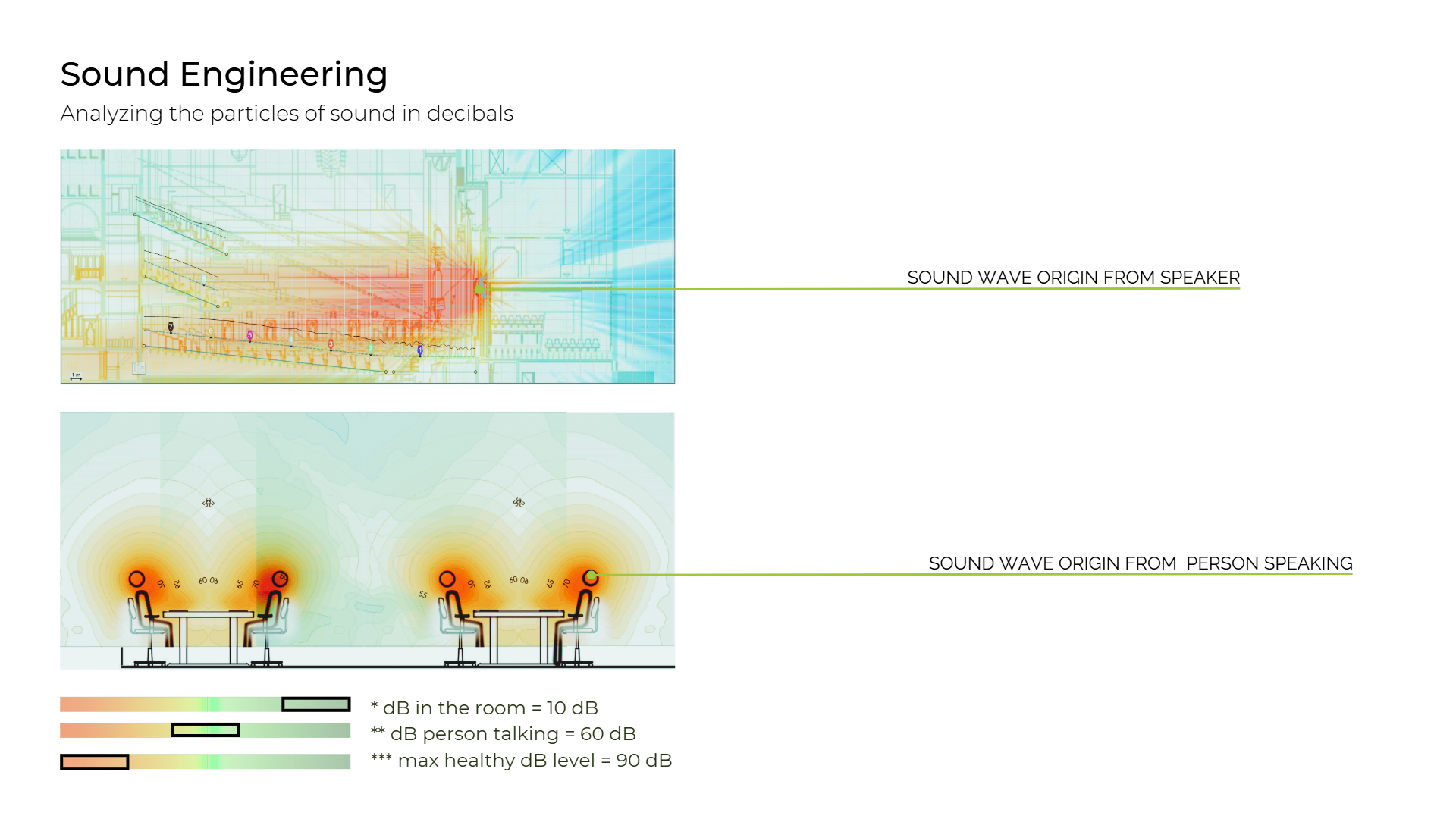

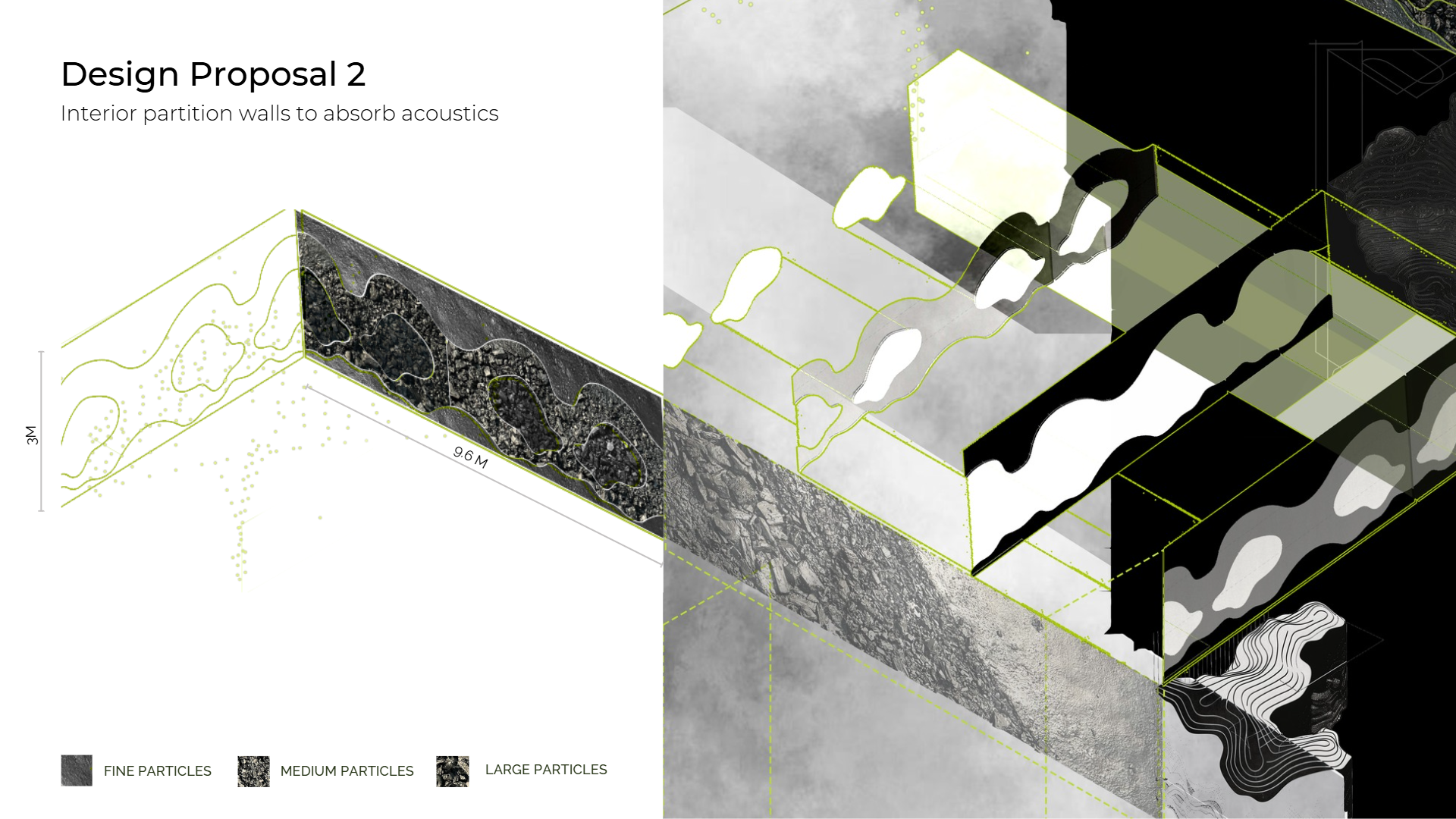

Analysis for Proposal 2

Proposal 2 - Interior Partition Walls

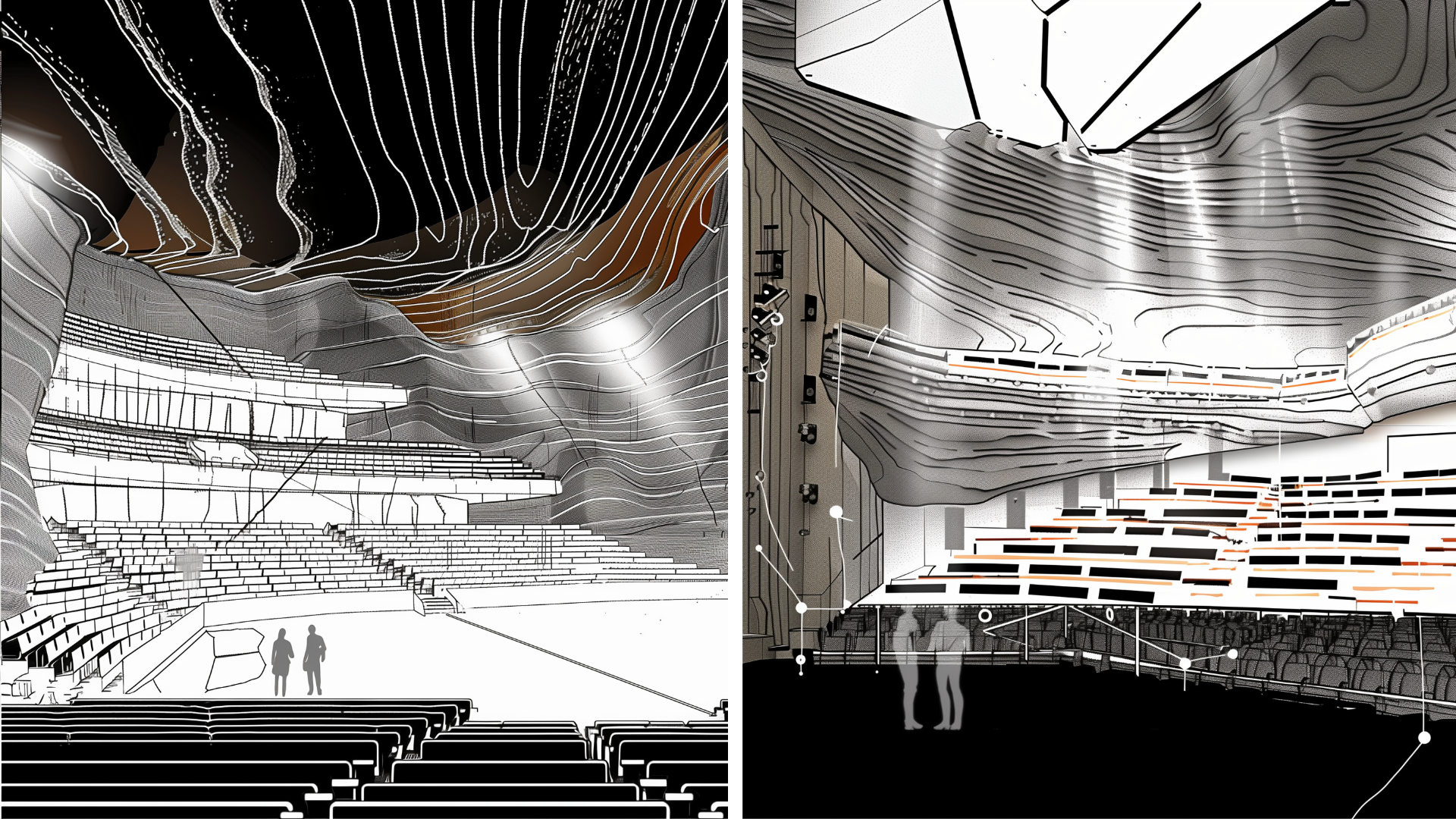

Proposal 1 Visualization

Proposal 2 Visualization