|TreeWise

Timber Sensing Technology

|Team

Clara Edith Carmona Hernandez, Maria Alejandra Rodriguez Morales, Nitsan Mor, Sunida Sailasuta

|Faculty

Areti Markopoulou, Nikol Kirova, Daniil Koshelyuk

|Project year

2023-24

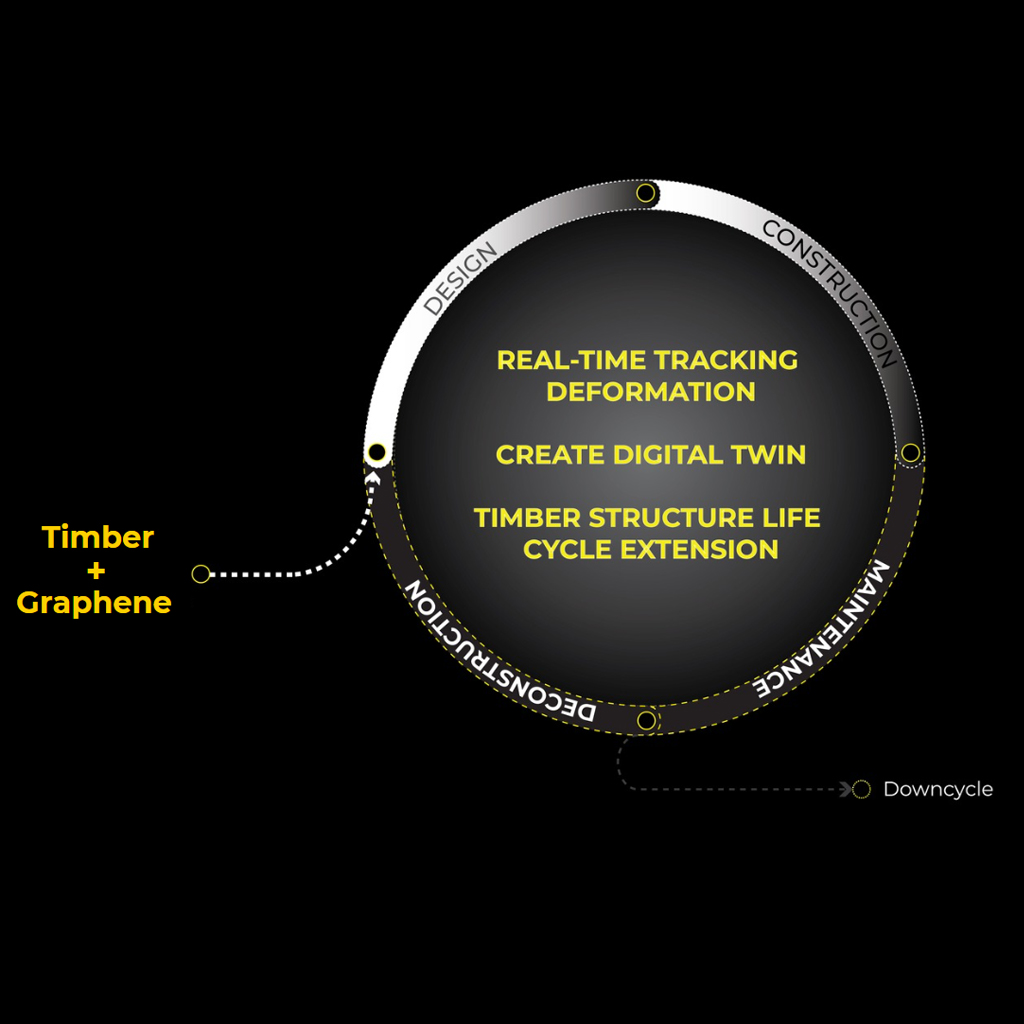

TreeWise strives to replace traditional sensors through combining timber and graphene. This innovative approach allows real-time tracking of deformations inside the wood, creation of a digital twin that aims to improve maintenance efficiency in the operational phase and providing a detailed service life passport to extend the life cycle of timber structures.

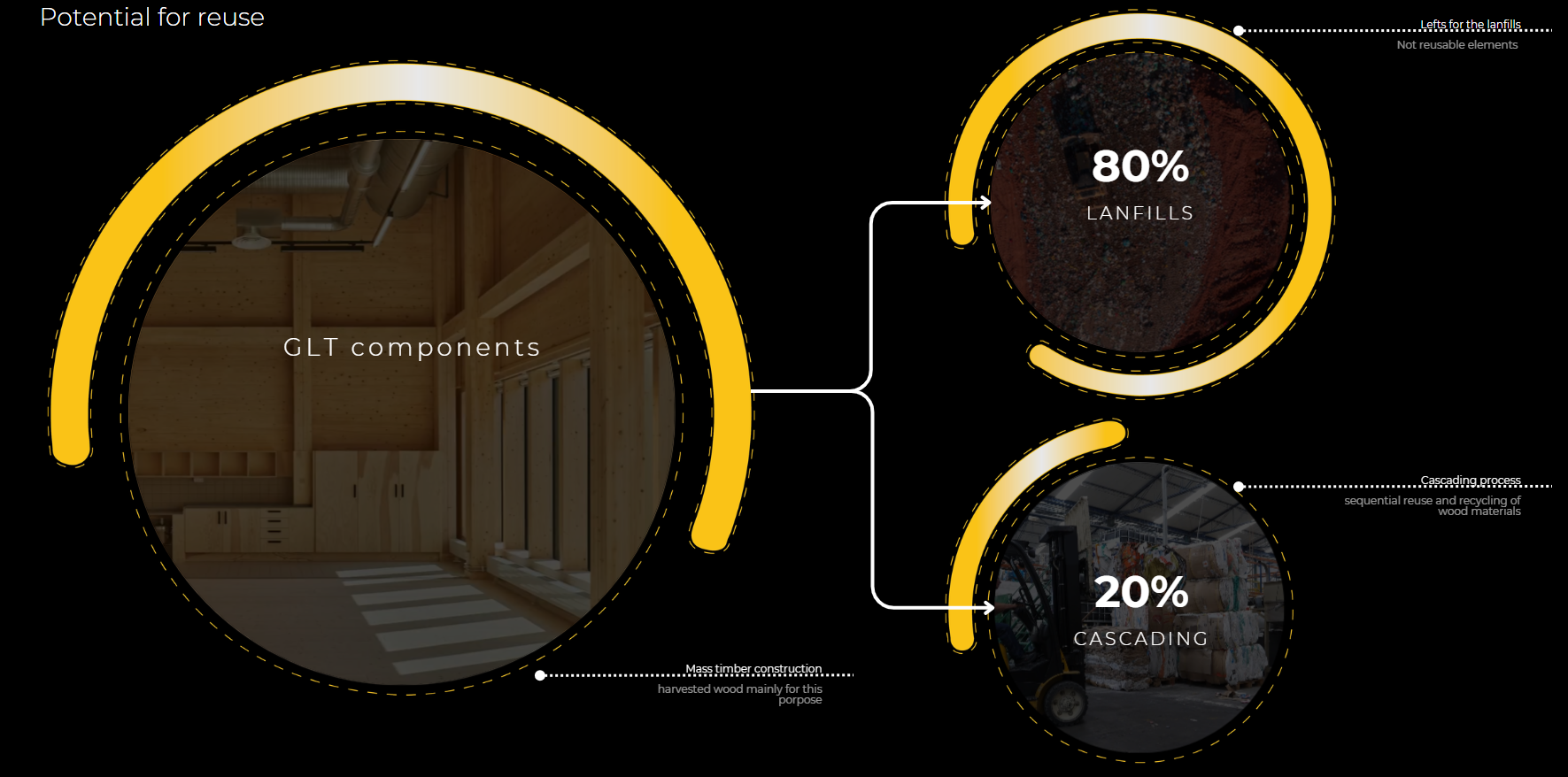

While timber construction offers carbon sequestration benefits, 80% of timber waste still ends up in landfills, despite the fact that 95% of components are recyclable.

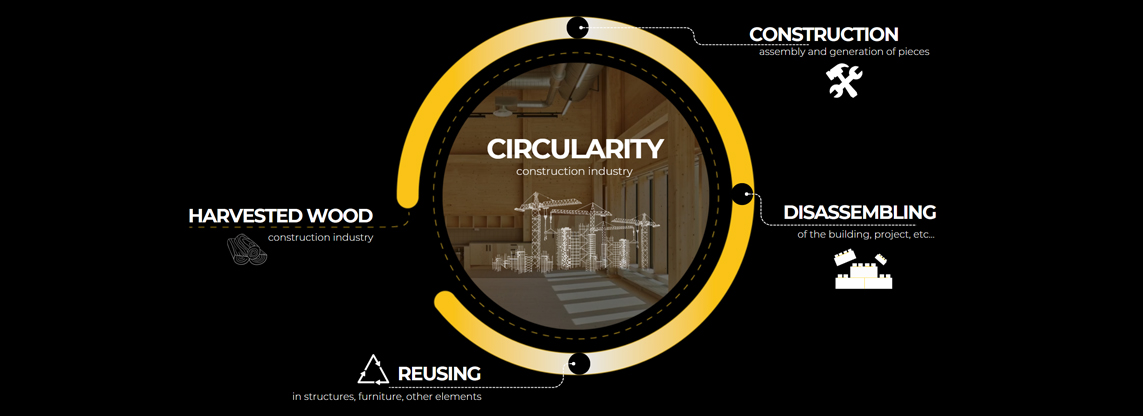

Wood is a versatile and sustainable biomaterial with immense potential for the construction industry. It serves as a natural carbon sink during its life cycle and can be reintegrated into the soil at the end of its use. However, the growing adoption of mass timber construction—relying on engineered and glue-laminated timber (GLT)—brings challenges related to resource efficiency and waste management.

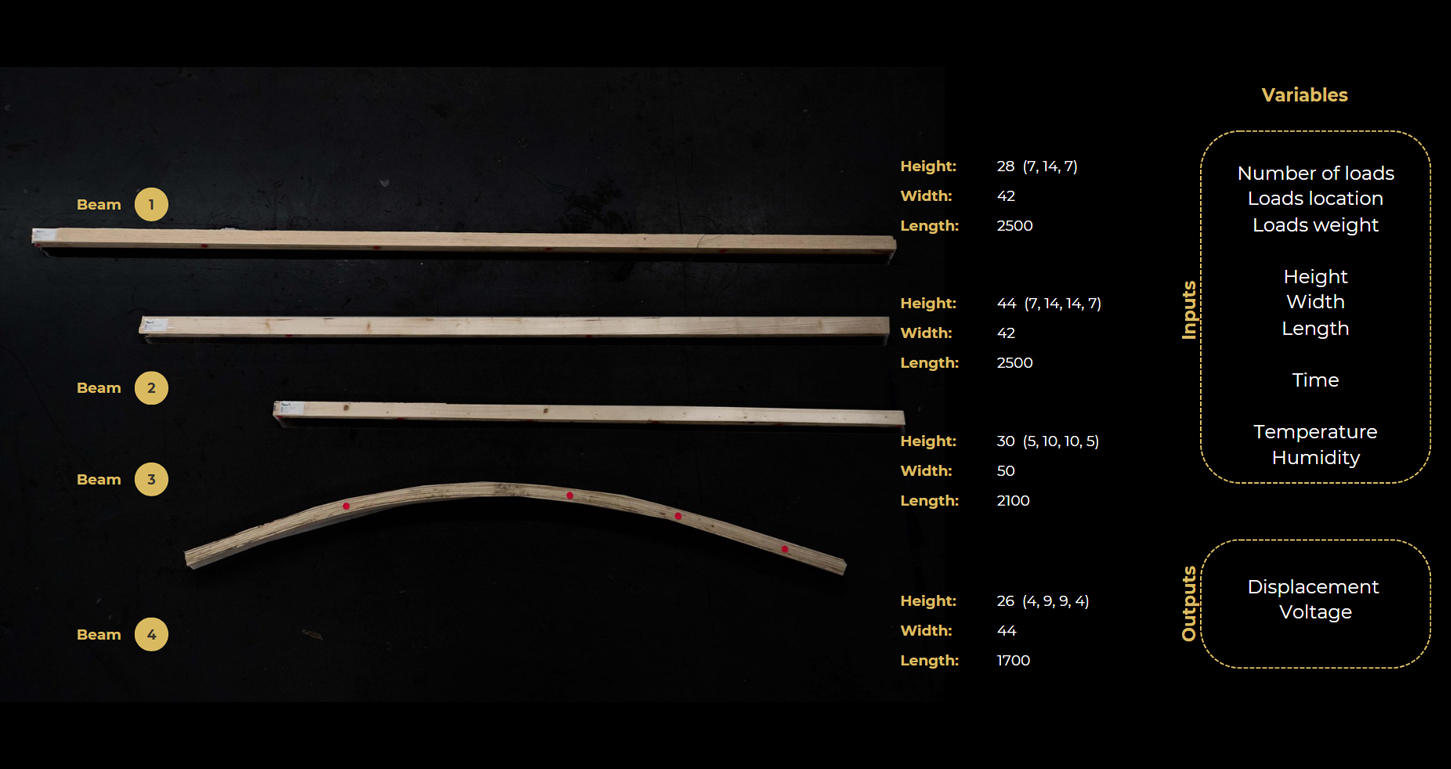

This project proposes an innovative material system combining timber and graphene to address the limitations of current practices. Graphene, known for its high conductivity, capacitance, and biodegradability, offers advanced sensing and actuation capabilities that make it ideal for enhancing timber’s lifecycle. By integrating graphene ink into the top and bottom layers of glue laminated timber, this project enables real-time monitoring of structural performance, deformation, and stress. This system replaces traditional, costly sensors and introduces a sustainable solution for tracking timber elements throughout their lifecycle.

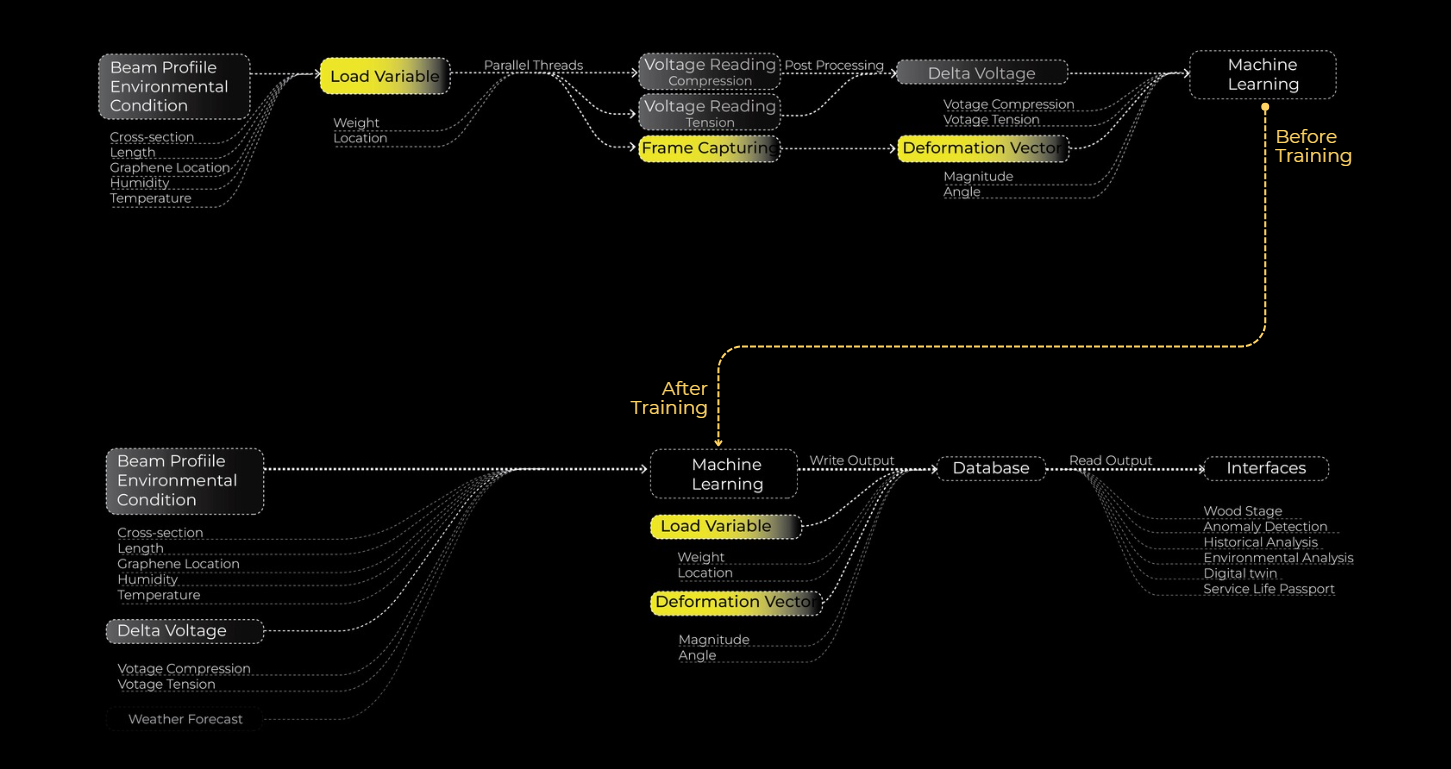

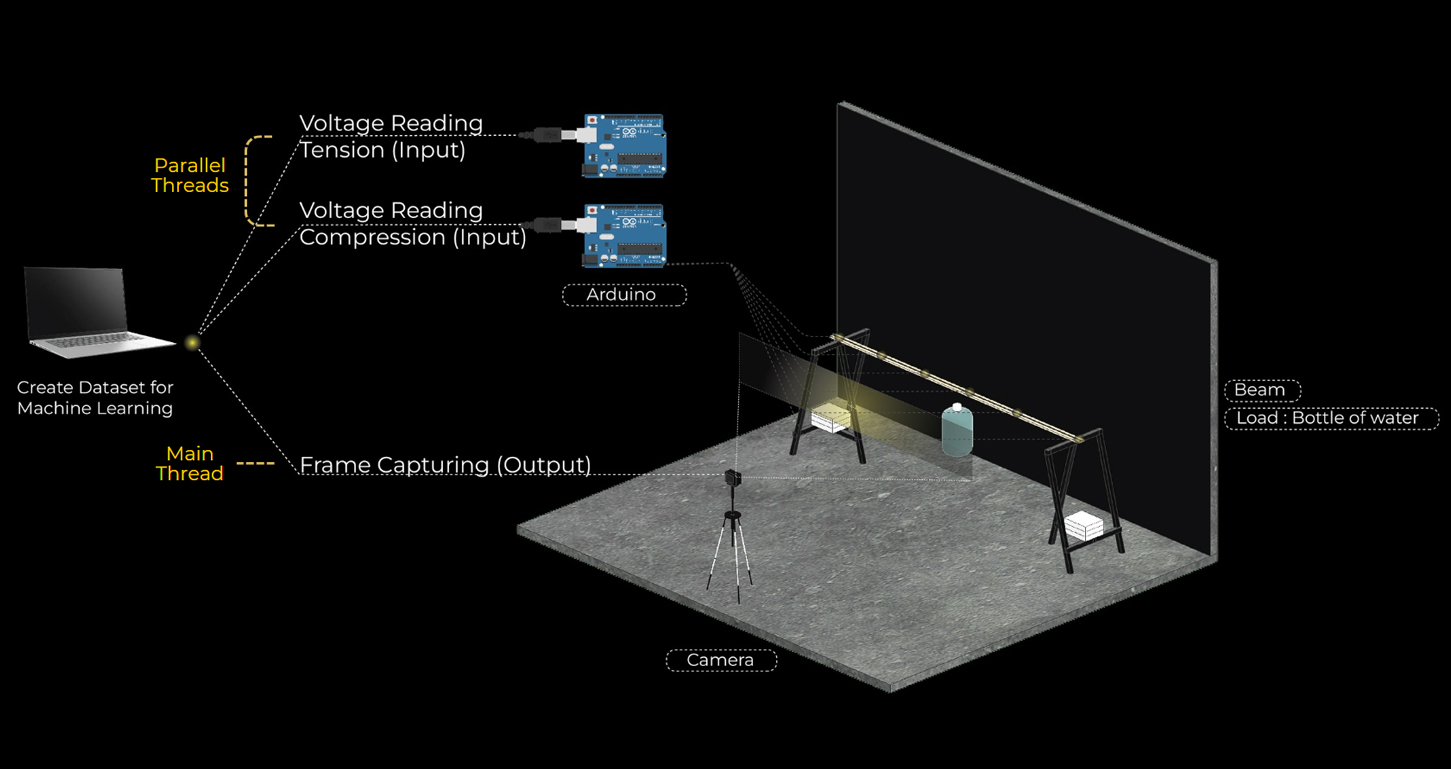

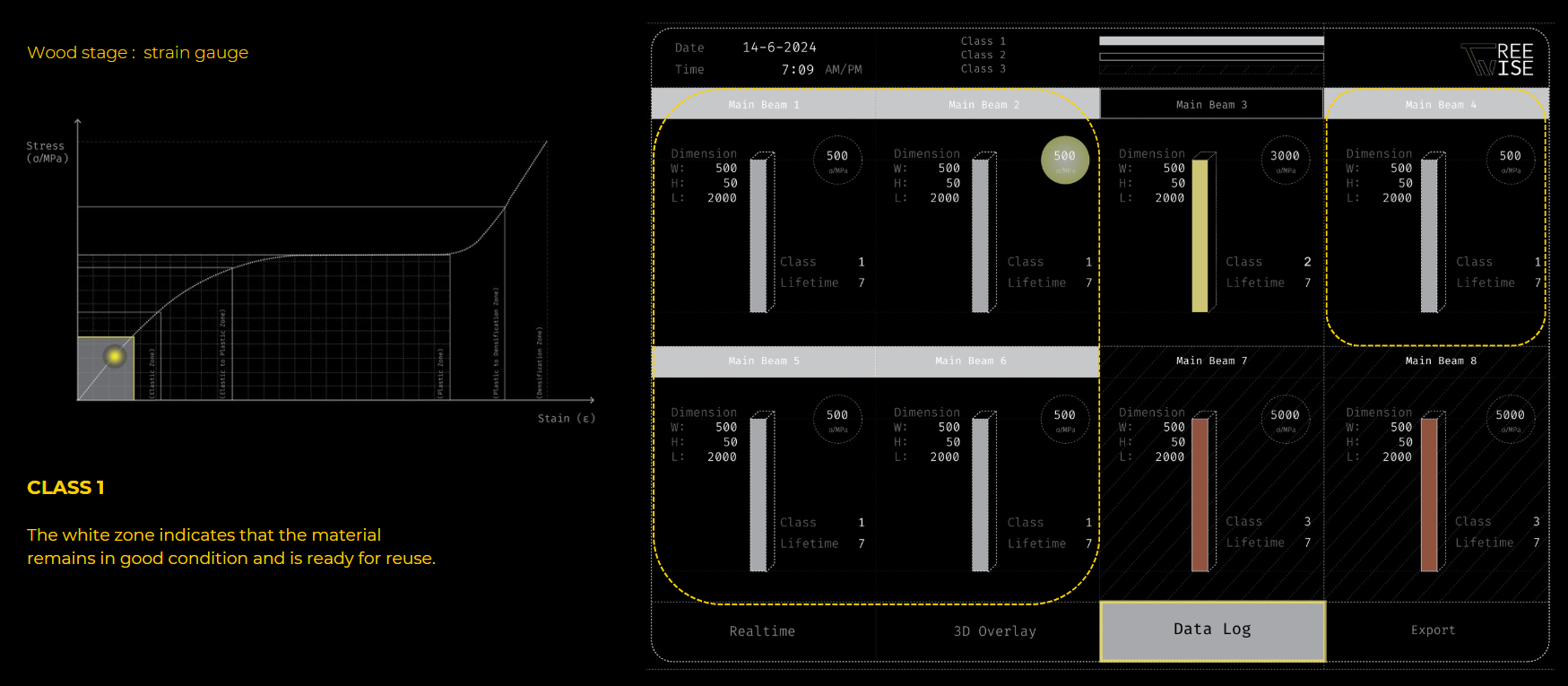

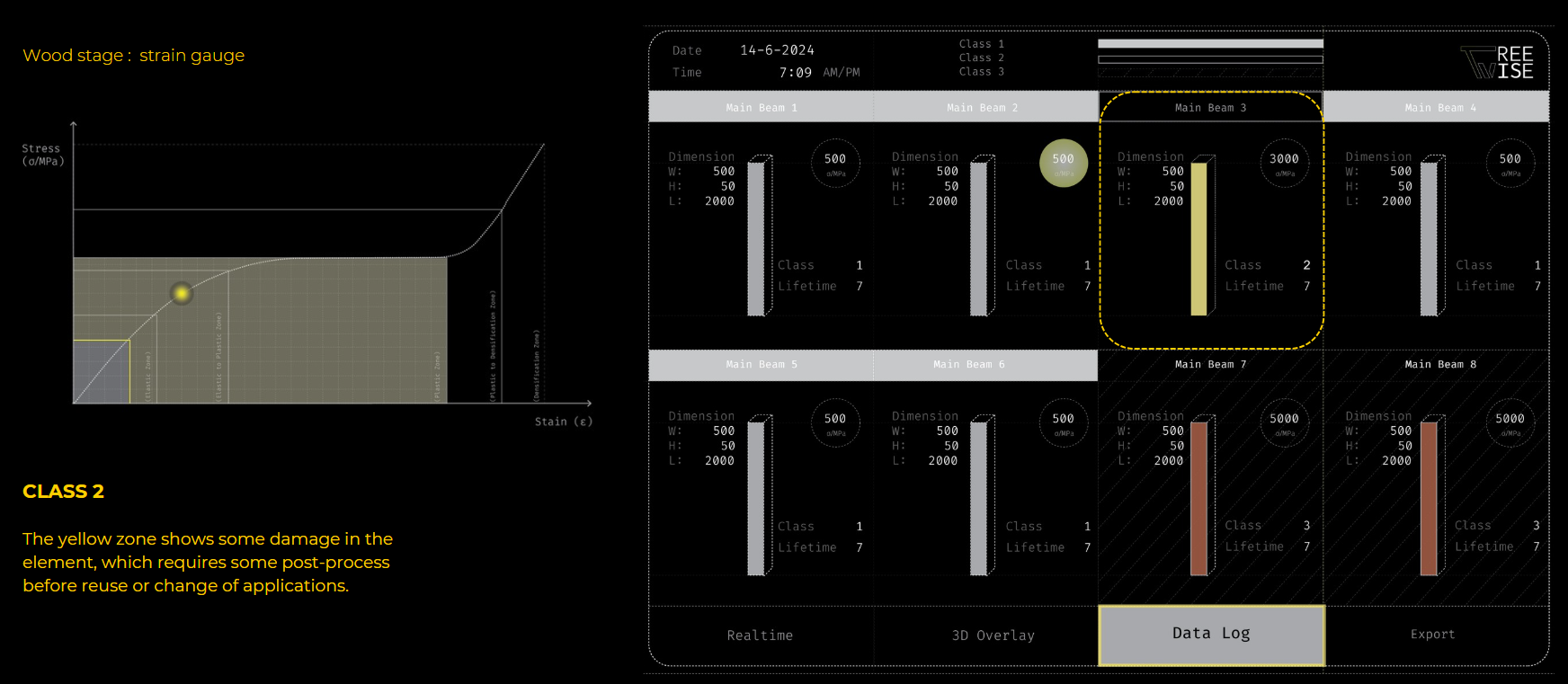

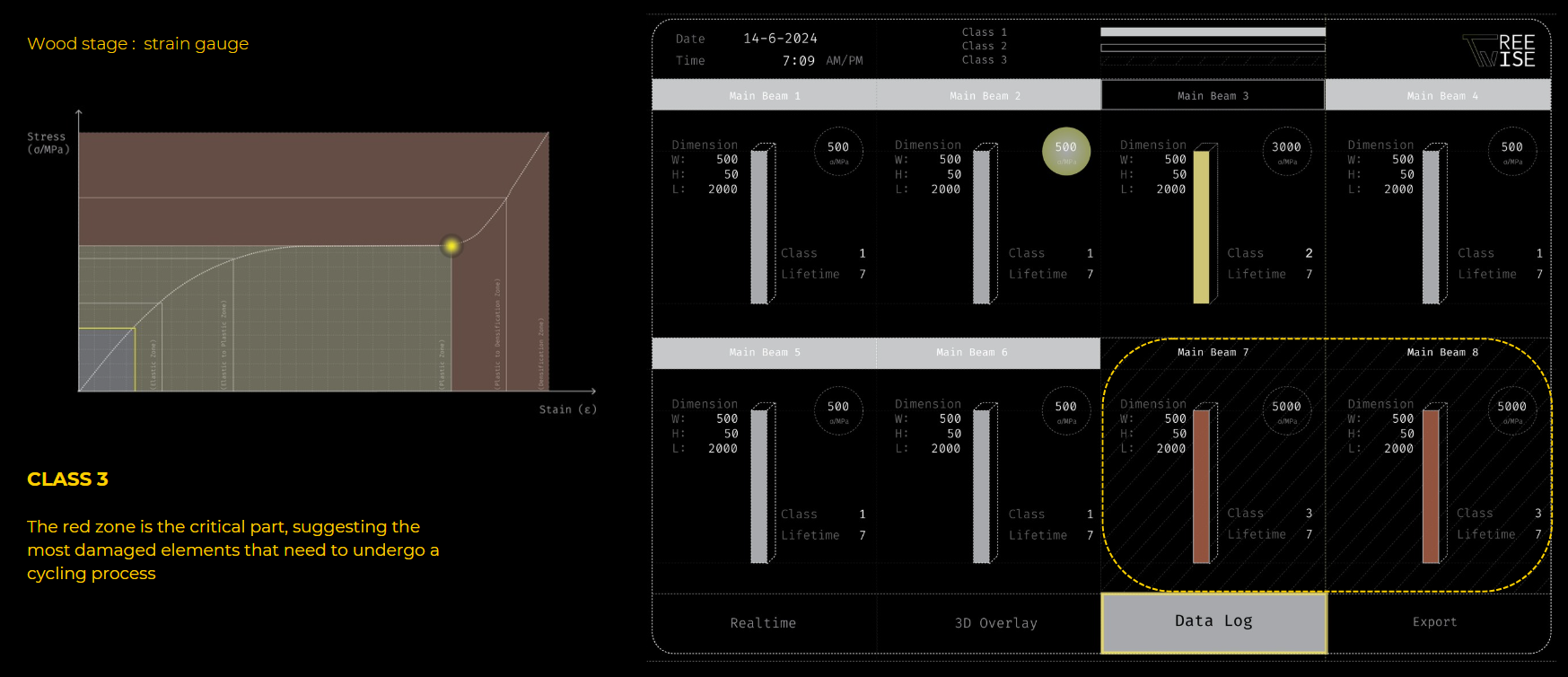

The monitoring system uses graphene’s sensitivity to changes in electrical resistance to detect load-induced deformations. When stress exceeds the timber’s elastic zone, the system triggers maintenance alerts or categorizes the element for reuse based on deformation data. To achieve this, a machine learning model was trained using a comprehensive dataset of voltage changes, deformation vectors, and environmental conditions.

Machine Learning Workflow

Material Processing

Prototypes for ML Training Data Set

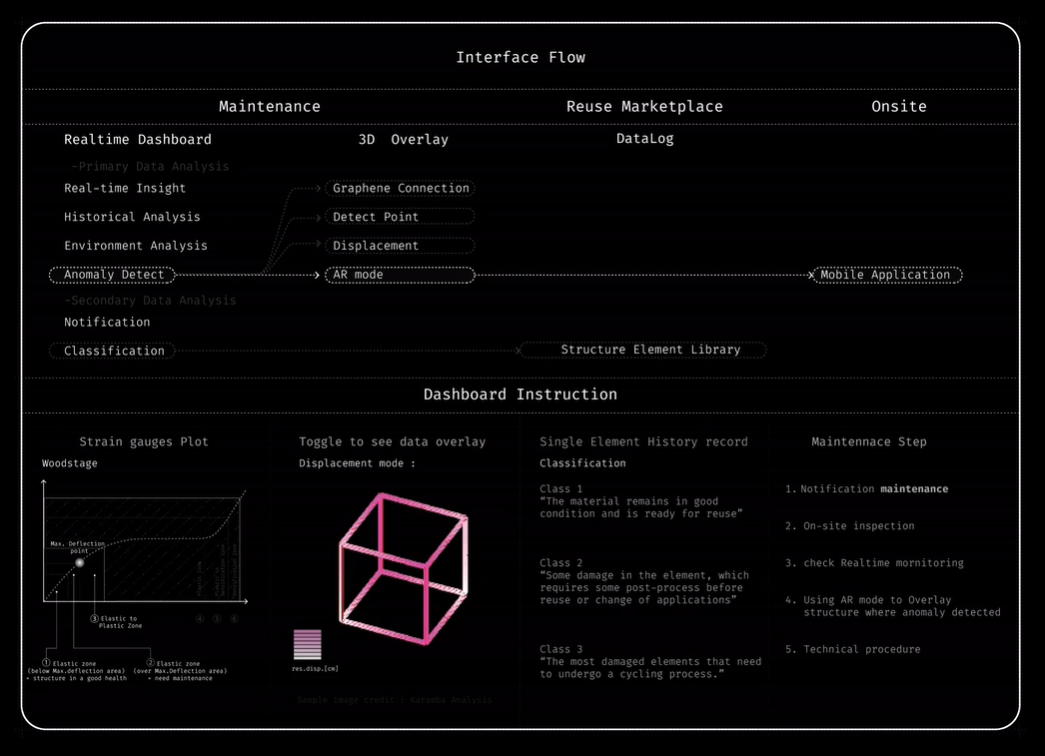

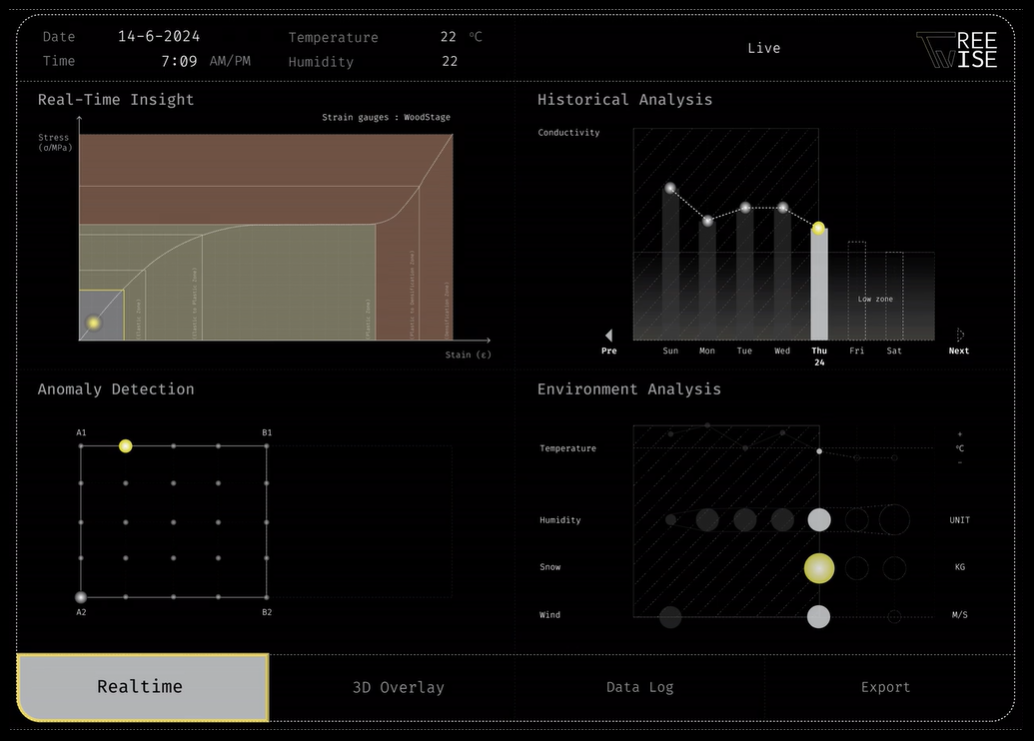

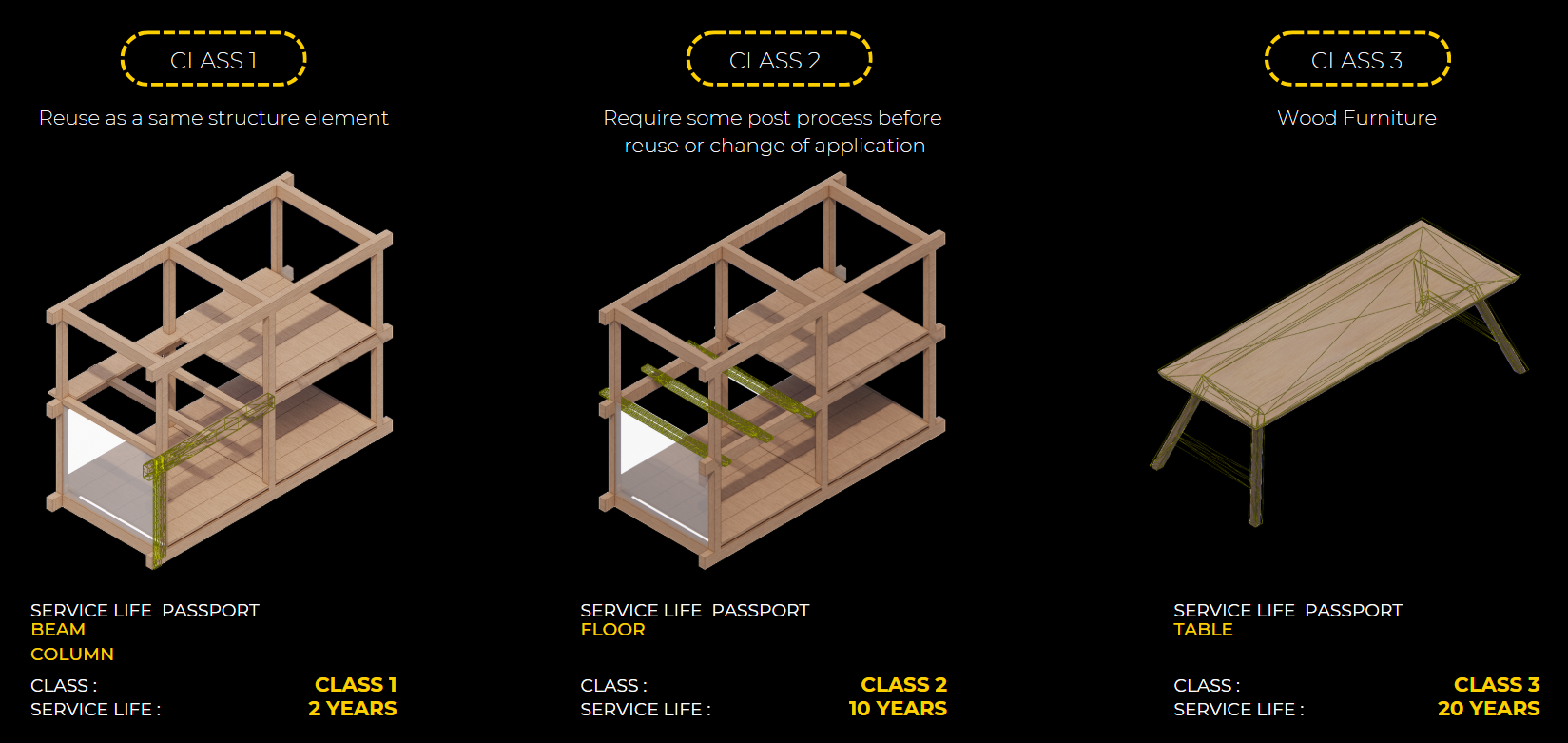

This data is managed through a digital twin—a virtual representation of the timber elements—that provides a service life passport for each component. The digital twin tracks material performance, records environmental factors such as humidity and weather, and categorizes elements for reuse. An interactive dashboard is also developed for offering real-time monitoring, anomaly detection, and weekly maintenance reports, streamlining facility management and extending the lifespan of timber structures.

Interactive Dashboard

Interactive Dashboard

Interactive Dashboard

Service Life Passport Class 1

Service Life Passport Class 2

Service Life Passport Class 3

Service Life Passport