|ReClay(m)

The old builds the new

|Team

Evangelia Sarantopoulou, Snehal Pare, Yuvraj Shirke

|Faculty

Areti Markopoulou, Nikol Kirova

|Project year

2022-23

Re-clay(m) is a local solution to the global problem of construction and demolition waste. In this context, the raw material utilized in the form of brick, a widely available resource all around the world, obtained from the construction demolition waste. The primary objective is to promote the upcycling process and facilitate the transition towards a circular economy and reduction of carbon emission within the brick construction demolition waste industry. By harnessing the abundance of brick waste, its favorable mechanical properties, and its suitability for compression construction, it gives way design diverse structural systems.

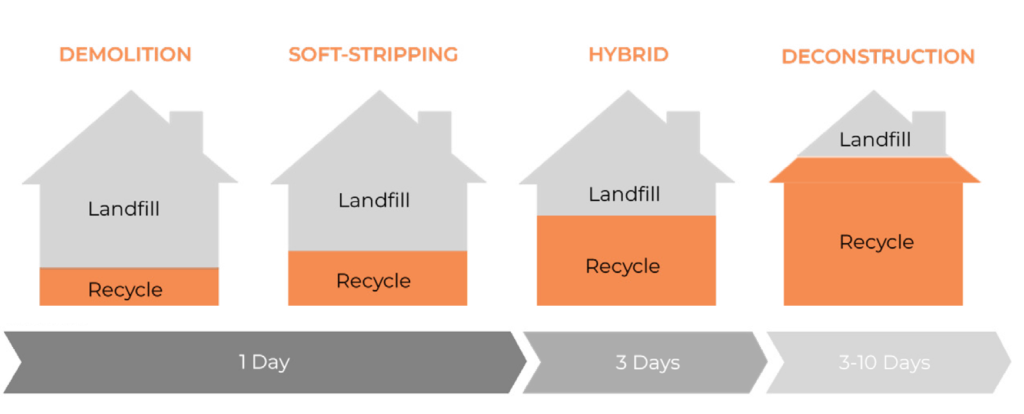

The goal is a regenerative system emphasizing durability, recyclability, and collaborative consumption. Our systematic building deconstruction approach aims for efficient dismantling, prioritizing resource recovery and waste reduction.

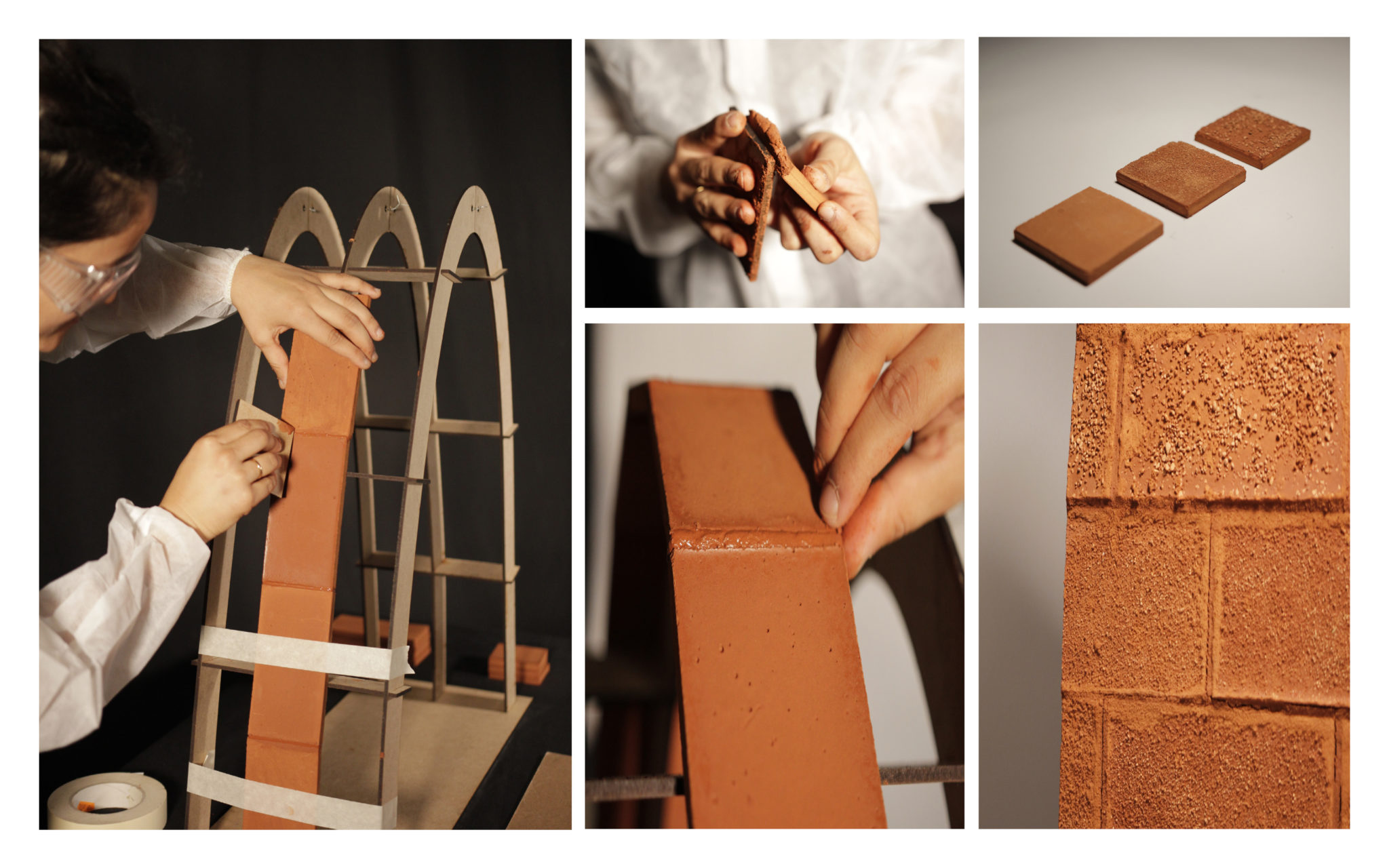

The initiative involved conducting experiments to assess the mechanical properties of this material. Additionally, it aimed to create brick powder geopolymers and composite modules using brick aggregates, varying in strength, size, and geometry. These modules were tailored to meet specific structural requirements, envisioning their use in constructing a funicular structure that aligns with traditional brick construction methods.

Brick disintegration, triggered by high-temperature exposure during production, transforms the clay’s structure, enhancing its pozzolanic properties. This makes it highly reactive, suitable for geopolymer composites. In-depth experimentation was conducted with brick powder to address post-drying deformations. Shrinkage, warping, and cracks were mitigated through fine-tuning the geopolymerization process. Various recipes, including mixed alkaline activators, metakaolin, and Geolite cement, were tested to achieve improved stability.

Brick Samples

Timbral Vault System

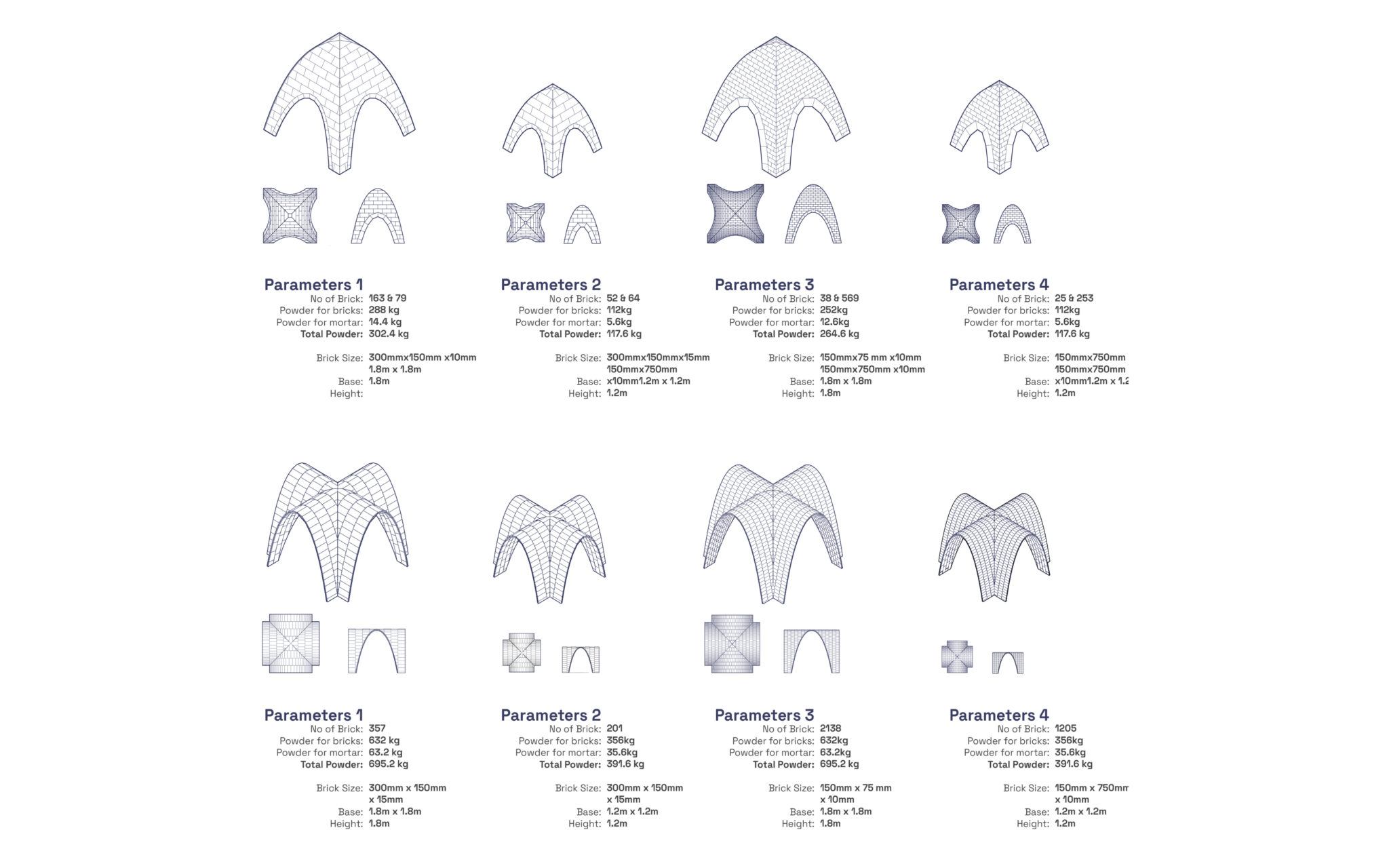

Vaults Design Catalogue

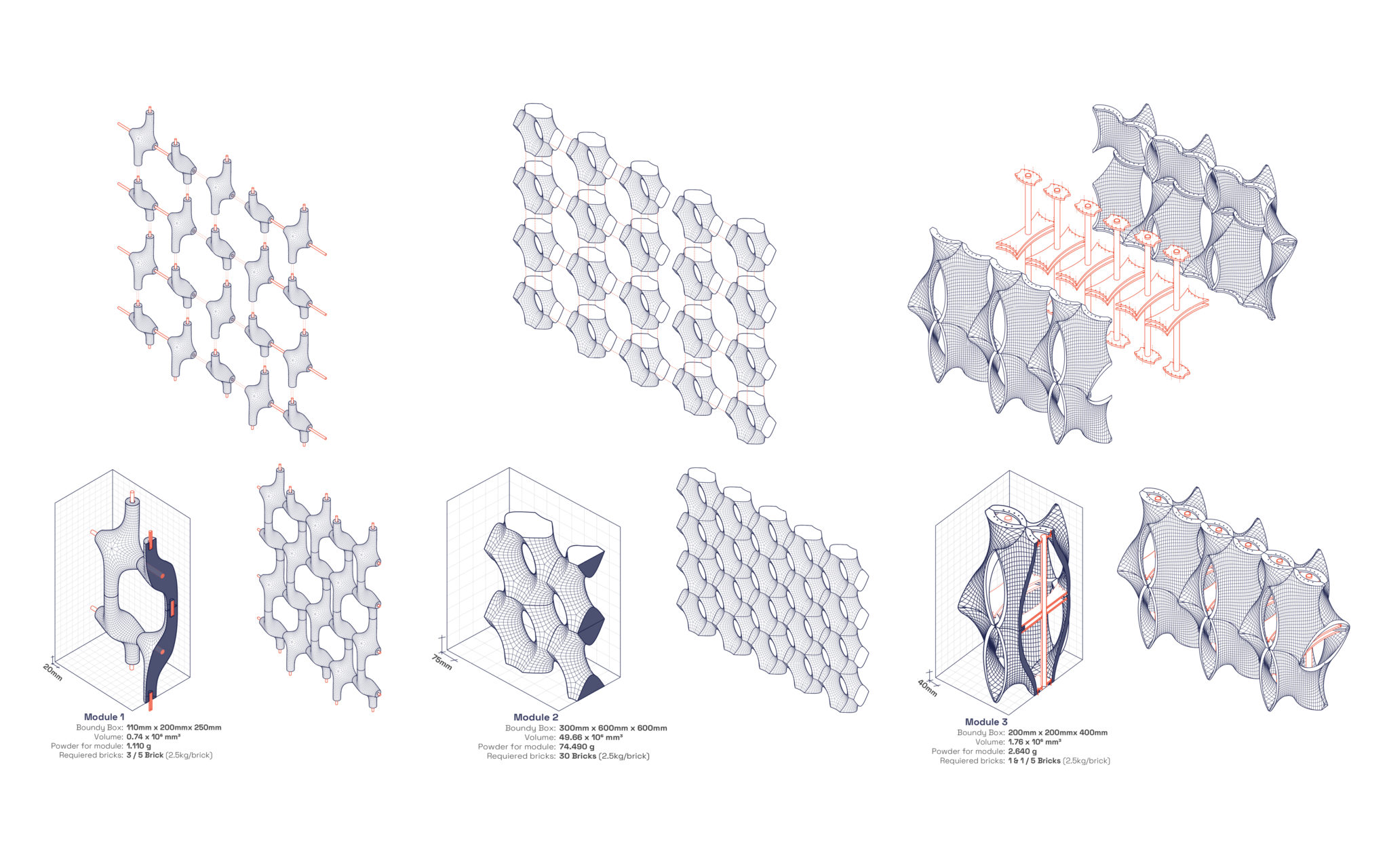

Geometric Component Catalogue

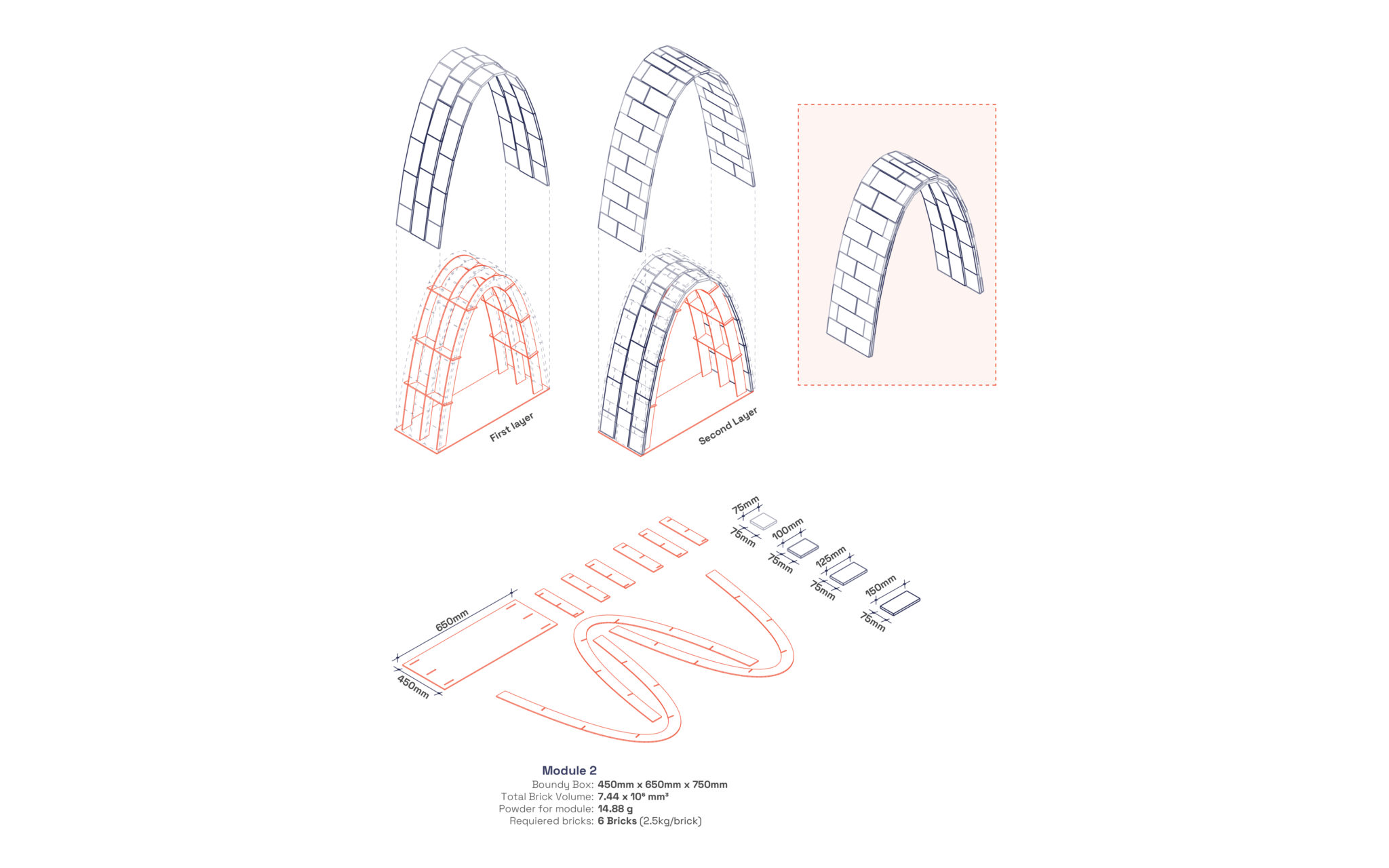

The timbrel vault construction method relies on the adhesion of multiple layers of overlapping tiles, which are securely bonded together with fast-setting mortar. To ensure structural stability, it is crucial to incorporate two or three layers of thin tiles into the design. As a result, the resulting laminated shell attains a strength comparable to that of reinforced concrete. Each module was carefully assigned specific prototypes and brick sizes, strategically placed with variations in layering to achieve the desired structural integrity. The project also involved exploring various geometric configurations, including cross vaults, ribbed vaults, and doubly curved vault systems.

Additionally, investigations were conducted on geometries such as minimal surfaces, nodal geometry, and perforated blocks to examine the material stability under different geometric conditions, taking into consideration the unique properties of the materials used.

Fabrication Vault Design

Fabrication process

Fabricated Vault

Through systematic testing and refinement, optimal recipes for materials were successfully identified. These materials have exhibited significantly improved stability, showcasing their potential as robust and sustainable construction elements. This breakthrough signifies a notable advancement in building technology, offering promising prospects for enhancing durability and eco-conscious construction practices.